Ammonia Inhibition in Anaerobic Digestion: Is It Silently Sabotaging Your Biogas Plant Performance?

If your biogas plant isn't hitting its expected gas yields, or you've noticed unexplained drops in performance, Ammonia Inhibition could be the hidden culprit. This common yet often overlooked challenge affects anaerobic digestion (AD) facilities worldwide, quietly eroding efficiency, reducing methane production, and increasing operational costs.

However, once you understand what ammonia inhibition is, how to spot it, and, most importantly, how to manage it, you can transform your plant's performance and protect your bottom line. Whether you're an AD plant operator, consultant, or business owner, this guide will give you the practical knowledge you need to tackle ammonia toxicity head-on.

What is Ammonia Inhibition in Anaerobic Digestion?

Ammonia inhibition occurs when free ammonia nitrogen (FAN) or ammonium nitrogen (NH₄⁺) accumulates in your digester to toxic levels, disrupting the delicate microbial communities responsible for biogas production. While nitrogen is essential for microbial growth, too much of it, particularly in its free ammonia form, becomes toxic to the methanogens (methane-producing microorganisms) that drive your AD process.

The Science Behind Ammonia Toxicity

During anaerobic digestion, organic nitrogen from feedstocks (like animal manure, food waste, or energy crops) is broken down into ammonia. This ammonia exists in equilibrium between two forms:

Ammonium ion (NH₄⁺): The less toxic, ionised form

Free ammonia (NH₃): The highly toxic, un-ionised form

The balance between these two forms is heavily influenced by pH and temperature. Higher pH levels (above 7.5) and elevated temperatures shift the equilibrium towards free ammonia, which is the form that's toxic to methanogens. This is why seemingly small changes in operating conditions can trigger sudden performance drops.

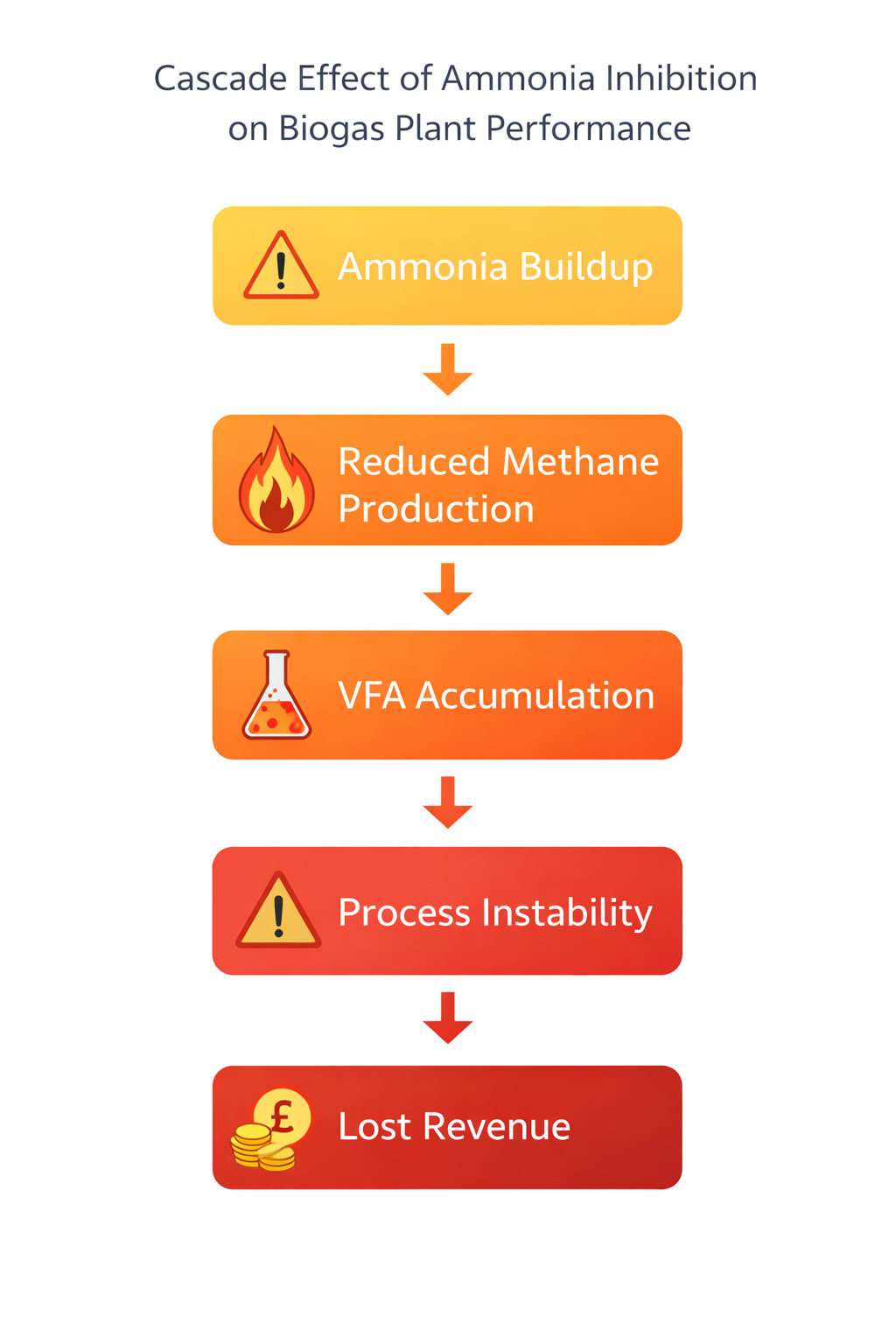

How Ammonia Inhibition Decreases Site Performance

The impact of ammonia inhibition on your AD plant can range from subtle efficiency losses to complete process failure. Here's how it manifests:

1. Reduced Biogas and Methane Yields

When methanogens are inhibited, they can't efficiently convert volatile fatty acids (VFAs) into methane. The result? Lower biogas production and reduced methane content in your gas output. For commercial operations, this translates directly to lost revenue from reduced energy generation or reduced gas-to-grid export volumes.

2. VFA Accumulation and pH Imbalance

As methanogen activity slows, VFAs begin to accumulate in the digester. This creates a cascade effect: VFA buildup lowers pH, which can further stress the remaining microbial population and create an increasingly unstable process. You may notice your digester becoming "sour" or acidic, which is a classic warning sign of process imbalance.

3. Process Instability and Increased Downtime

Ammonia inhibition rarely announces itself clearly. Instead, operators often experience erratic performance, unexplained foaming, increased odour complaints, and difficulty maintaining stable operating parameters. This instability increases the risk of unplanned shutdowns and emergency interventions, both of which are costly and disruptive.

4. Poor Digestate Quality

Elevated ammonia levels can affect the quality of your digestate output, potentially impacting its value as fertiliser or its compliance with quality standards like PAS 110. This can reduce your revenue streams and limit end-market options.

5. Increased Operational Costs

Managing ammonia inhibition often requires additional inputs, whether that's dilution water, process additives, pH buffers, or increased monitoring and laboratory analysis. Recovery from severe inhibition may require extended stabilisation periods, during which your plant operates well below capacity.

Common Causes of Ammonia Inhibition

Understanding what triggers ammonia buildup is the first step toward prevention. Here are the most common culprits:

| Cause | Why It Matters | Risk Level |

|---|---|---|

| High-protein feedstocks | Poultry manure, abattoir waste, and certain food wastes contain high nitrogen content that breaks down into ammonia | High |

| Overloading organic loading rate (OLR) | Feeding too much substrate too quickly overwhelms the microbial population and accelerates ammonia release | High |

| Poor C:N ratio management | Insufficient carbon relative to nitrogen prevents balanced digestion and promotes ammonia accumulation | High |

| High digester temperature | Thermophilic conditions (above 50°C) increase free ammonia formation | Medium-High |

| Elevated pH | pH above 7.5 to 8.0 shifts equilibrium towards toxic free ammonia | Medium-High |

| Inadequate mixing | Poor mixing creates zones of high ammonia concentration and prevents uniform distribution | Medium |

| Lack of trace elements | Deficiencies in cobalt, nickel, or selenium can stress methanogens, making them more vulnerable to ammonia | Medium |

Many AD plants unknowingly create ammonia problems by blending feedstocks without considering their combined nitrogen load. Always calculate your total nitrogen input and target C:N ratios before adjusting feed recipes.

Warning Signs Your Plant May Be Suffering from Ammonia Inhibition

Catching ammonia inhibition early can save you from costly process failures. Watch for these red flags:

Operational Indicators

Declining gas production: Gradual or sudden drops in daily biogas yield

Reduced methane content: Lower CH₄ percentage in your gas analysis

Rising VFA levels: Propionic and butyric acid concentrations increasing over time

pH instability: Difficulty maintaining stable pH, or pH creeping above 8.0

Foaming issues: Excessive foaming that's difficult to control

Unusual odours: Strong ammonia smell around the plant or in digestate

Laboratory Results

Total ammonia nitrogen (TAN) >3,000 mg/L: Levels above this threshold typically indicate risk

Free ammonia nitrogen (FAN) >150 to 200 mg/L: This is where serious inhibition begins for most systems

VFA/alkalinity ratio >0.3: Suggests process imbalance

Increasing VFA concentrations: Particularly propionic acid buildup

Different microbial communities have varying tolerances to ammonia. Some well-acclimated systems can handle TAN levels up to 5,000 mg/L or higher, while others struggle above 2,500 mg/L. Regular monitoring and understanding your specific system's baseline is crucial.

How to Optimise Your AD Plant and Prevent Ammonia Inhibition

Ammonia inhibition is manageable with the right strategies. Here's how to optimise your plant and keep your methanogens happy:

1. Feedstock Management and C:N Ratio Balancing

Your feedstock recipe is your first line of defence. Aim for a carbon-to-nitrogen (C:N) ratio between 20:1 and 30:1 for optimal digestion. If you're processing high-nitrogen materials like poultry litter or food processing waste, balance them with carbon-rich co-substrates such as:

Straw or crop residues

Energy crops (maize silage, grass silage)

Cardboard or paper waste

Glycerine

Fats, oils, and grease (FOG)

Actionable step: Create a feedstock management spreadsheet that tracks the nitrogen content of each input. Calculate your daily total nitrogen load and adjust your recipe accordingly. This simple practice can prevent most ammonia-related problems before they start.

2. Process Monitoring and Early Intervention

You can't manage what you don't measure. Implement a robust monitoring programme that includes:

Daily parameters: Gas production, methane content, pH, temperature

Weekly laboratory testing: TAN, FAN, VFA profile, alkalinity

Monthly performance audits: Trend analysis to spot gradual changes

Consider investing in online monitoring systems that provide real-time data on critical parameters. Early detection allows for corrective action before inhibition becomes severe. Many modern AD plants use automated systems that alert operators to deviations from normal operating ranges.

3. pH and Temperature Management

Remember that free ammonia formation increases with both pH and temperature. If your system is experiencing elevated ammonia:

Control pH: Keep pH in the range of 7.0 to 7.5 where possible. Consider pH adjustment if levels creep above 7.8

Review temperature: If operating thermophilically (>50°C), consider whether the benefits outweigh the increased ammonia risk. Some plants successfully reduce inhibition by shifting from thermophilic to mesophilic operation (35 to 40°C)

4. Hydraulic Retention Time (HRT) Optimisation

Longer retention times give your microbial population more time to adapt to higher ammonia levels. If you're experiencing inhibition, consider:

Reducing organic loading rate (OLR)

Increasing digester volume (where possible)

Operating with a longer HRT to allow microbial acclimation

Typical HRT ranges from 15 to 40 days depending on feedstock and system design. Plants dealing with high-nitrogen inputs may benefit from retention times at the upper end of this range.

5. Trace Element Supplementation

Methanogens require specific trace elements to function optimally, particularly under stress conditions. Deficiencies in cobalt, nickel, selenium, iron, and molybdenum can reduce microbial resilience to ammonia. Consider:

Regular trace element analysis of your digestate

Targeted supplementation based on laboratory results

Using purpose-formulated microbial nutrition additives

6. Ammonia Stripping and Dilution

For plants consistently battling high ammonia levels, technical solutions include:

Digestate recirculation and dilution: Using process water or digestate filtrate to reduce ammonia concentration

Ammonia stripping: Raising pH and aerating to drive off gaseous ammonia (though this requires careful environmental permitting)

Digestate separation: Removing liquid fraction to export nitrogen from the system

7. Biological Adaptation and Inoculation

Microbial communities can adapt to higher ammonia levels over time through gradual acclimation. If introducing new high-nitrogen feedstocks:

Ramp up gradually over several weeks

Monitor closely for signs of stress

Consider using adapted inoculum from other plants successfully digesting similar materials

Some operators have successfully used microbial additives specifically formulated for ammonia-stressed systems, though results vary and this should be considered alongside fundamental process management.

8. Professional Process Audits and Optimisation

Sometimes, the best investment is expert insight. Process optimisation consultants can conduct comprehensive audits that include:

Feedstock characterisation and C:N analysis

Microbial community assessment

Troubleshooting and bespoke recommendations

Long-term performance optimisation strategies

Industry specialists, such as those at BioConsult, provide technical consultancy services specifically designed to address performance challenges like ammonia inhibition. Their approach combines biological monitoring, process audits, and practical solutions to help AD operators maximise gas yields while maintaining stable, compliant operations.

Prevention is Better Than Cure

Ammonia inhibition doesn't have to be the silent productivity killer at your AD plant. With proper feedstock management, consistent monitoring, and proactive intervention, you can maintain stable biogas production, maximise yields, and avoid costly downtime.

The key is understanding that prevention is always easier and more cost-effective than recovery. Regular monitoring, balanced feeding strategies, and rapid response to early warning signs will keep your plant operating at peak performance.

Need Expert Support?

If you're concerned about ammonia inhibition at your site, or you'd like to optimise your plant's performance, consider reaching out to specialists who understand the complexities of AD processes. The team at BIOCON Group offers comprehensive support through their three specialist divisions:

BioConsult: Technical consultancy, process optimisation, and biological monitoring to help you identify and resolve performance issues

BioConstruct NewEnergy: Operational management, plant servicing, and gas yield improvement

BioContractors: Mechanical and electrical contracting, site maintenance, and technical support

With end-to-end expertise covering every aspect of AD plant operation, BIOCON Group can help you achieve consistent, compliant, and profitable biogas production.