Liquid Feeding in Anaerobic Digestion: What Is It and Why It Matters

Liquid feeding has become one of the most effective and reliable feeding methods in modern AD operations. Whether used in agricultural or industrial biogas plants, this approach offers improved process stability, easier handling and greater feedstock flexibility.

But what exactly is liquid feeding, and why is it increasingly being adopted across the UK and European AD sector?

What Is Liquid Feeding in AD?

Liquid feeding refers to the process of introducing pre-liquefied or pumpable feedstock into the digester. Unlike traditional solid or semi-solid feeding methods, where substrates are mechanically conveyed or pushed into the reactor, liquid feeding systems use pumps and pipework to deliver a consistent flow of substrate.

Feedstocks for liquid feeding are typically slurries, co-digestion mixtures, or pre-treated materials with a high liquid content. Common examples include:

Animal slurry and manure

Food waste slurries

Energy crops (e.g., maize silage, grass) processed via maceration or hydrolysis

Industrial residues and process water from food and beverage production

The key to liquid feeding is achieving the right viscosity and homogeneity, ensuring materials flow smoothly without clogging equipment or disrupting the digestion process.

How Does Liquid Feeding Work?

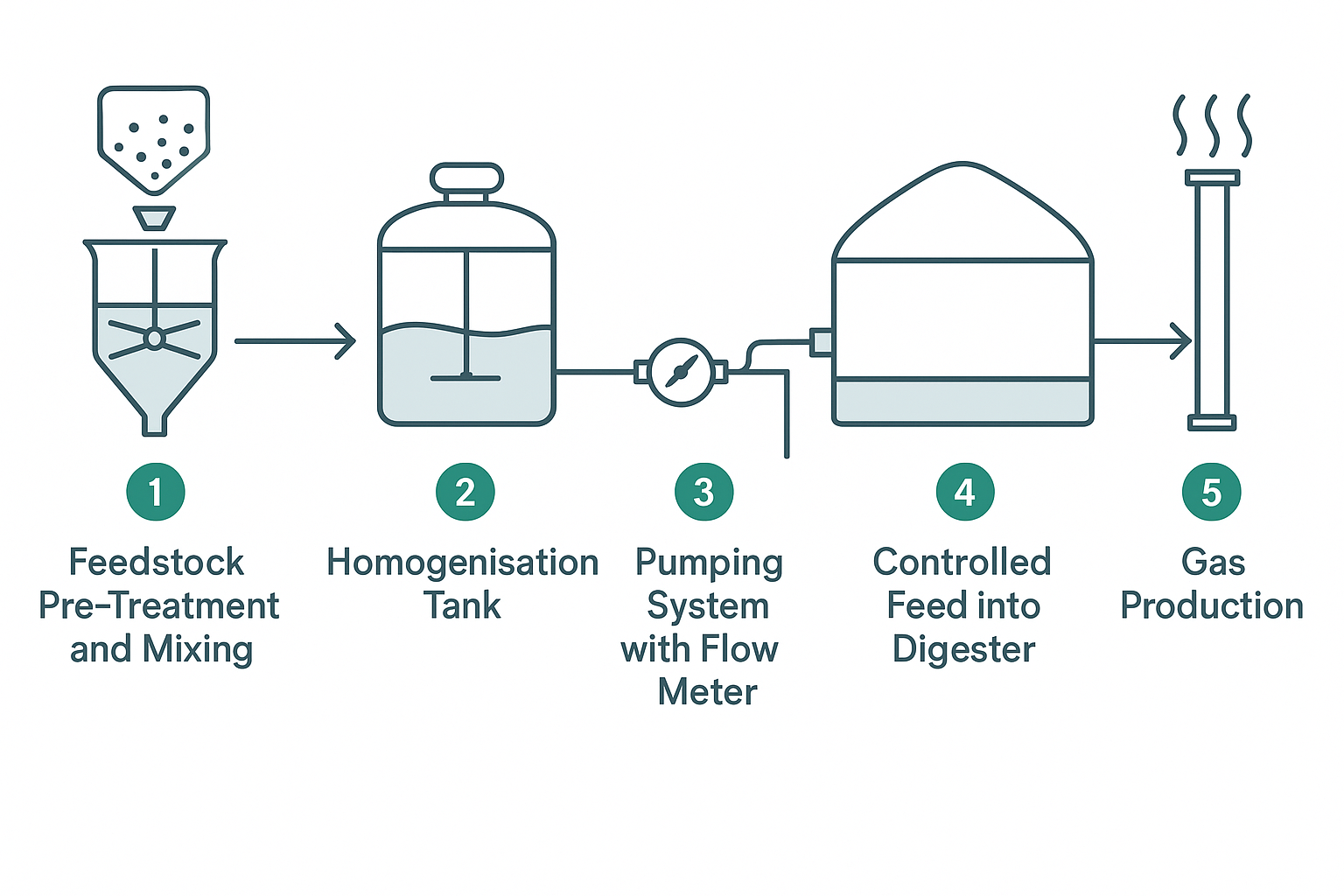

The process typically involves the following stages:

Pre-treatment or Mixing: Feedstocks are blended with recirculated digestate or process water to achieve a pumpable consistency.

Storage and Homogenisation: The mixture is stored in an intermediate tank equipped with agitation or mixing systems to maintain uniformity.

Metered Dosing: The substrate is pumped at a controlled rate into the digester, often using flow meters or automation systems to ensure precision.

Integration with Process Control: Many modern AD plants use automated systems that monitor feeding rates, biogas output, and digester health, adjusting inputs as required.

This approach provides a smooth and continuous feeding regime, reducing process shocks and maintaining stable microbial activity, this is a key factor in maximising methane yield.

Liquid vs Solid Feeding: What’s the Difference?

To highlight the distinctions, here’s a comparison of the two:

| Feature | Liquid Feeding | Solid Feeding |

|---|---|---|

| Feedstock Type | Slurries, pre-treated materials | Silage, crops, food waste, dry materials |

| Feeding Method | Pumped via pipeline | Conveyed or pushed via augers/screw feeders |

| Mixing Requirement | Lower – naturally homogenised | Higher – requires strong agitation |

| Operational Stability | High – smoother, steady-state feeding | Can fluctuate due to uneven loading |

| Maintenance | Lower – fewer blockages | Higher – mechanical wear and tear |

| Energy Use | Low | Higher |

| Capital Cost | Moderate | Often higher (system dependent) |

Liquid feeding provides a more controllable and energy-efficient method of supplying feedstock, particularly for plants seeking to maintain high process stability and throughput.

Advantages of Liquid Feeding Systems

Implementing a liquid feeding system can significantly improve plant performance. Some of the core benefits include:

1. Improved Process Stability

Continuous and consistent feeding helps maintain steady microbial activity, reducing the risk of acidification, foaming, or biogas fluctuations.

2. Enhanced Feedstock Flexibility

Liquid systems can easily handle a wide variety of feedstocks, including co-digested mixtures of slurry, food waste, and energy crops. This allows operators to adapt to seasonal availability or changing market conditions.

3. Reduced Maintenance and Downtime

Because feedstocks are pre-liquefied, the risk of blockages, bridging, or mechanical failures in feeding systems is significantly reduced.

4. Optimised Mixing and Retention

Liquid substrates distribute more evenly within the digester, ensuring optimal contact between microbes and feedstock — improving conversion efficiency and methane yield.

5. Energy Efficiency

Pumping liquids consumes less power compared to running augers or mixers continuously. This translates into lower parasitic energy demand and improved overall plant efficiency.

Potential Drawbacks of Liquid Feeding Systems

While liquid feeding offers numerous benefits, it also presents a few challenges that operators should consider before implementation:

Higher water content – Diluting substrates to create pumpable mixtures can reduce overall organic loading rate (OLR), potentially lowering methane output per cubic metre of digester volume.

Increased storage needs – Liquid substrates require larger buffer or mixing tanks, which can add to site footprint and infrastructure cost.

Potential for dilution of nutrients – Excess water in the system can alter nutrient concentrations, impacting microbial balance if not carefully monitored.

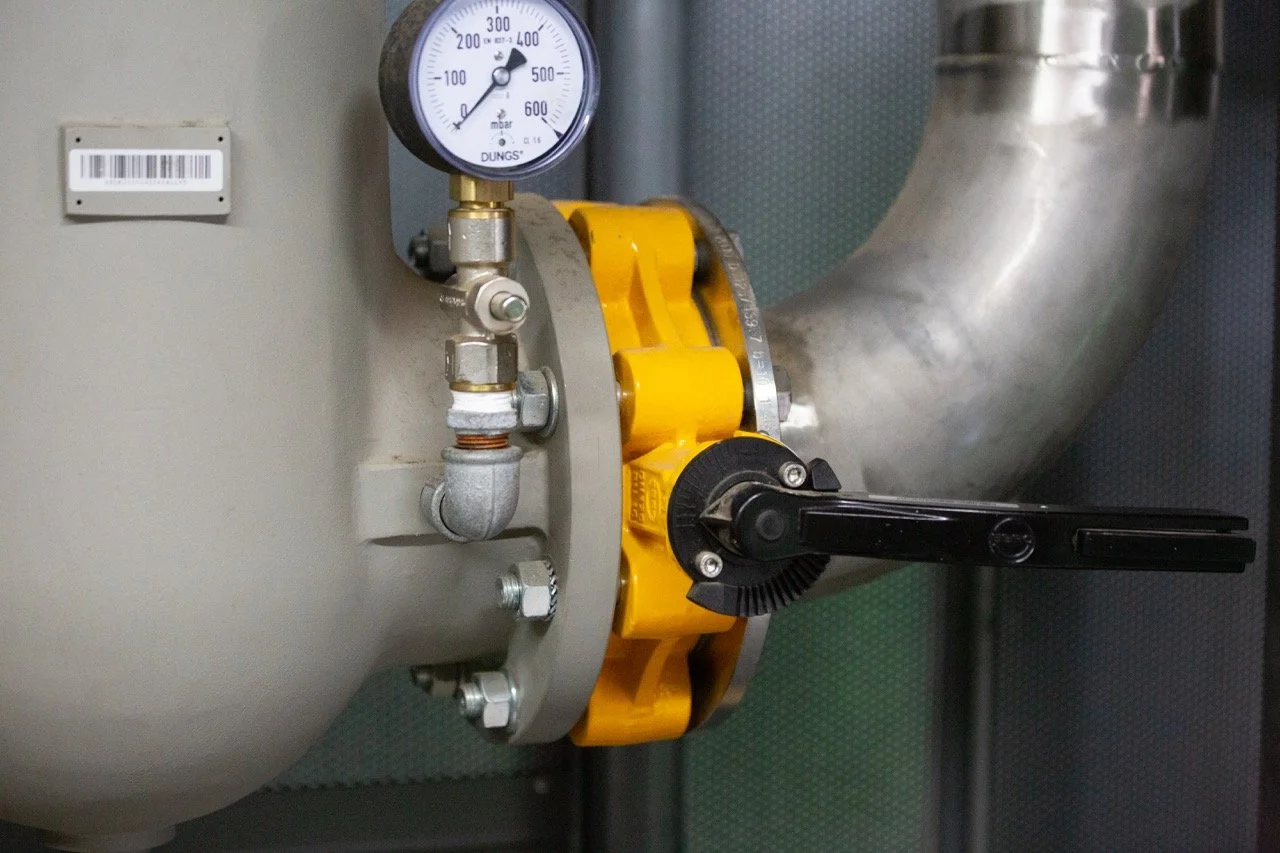

Additional pumping and pipe maintenance – Though less frequent than auger failures, pumps and valves in liquid systems still require periodic cleaning and inspection to prevent clogging.

Understanding these limitations helps ensure that liquid feeding is applied effectively and economically, balancing process stability with throughput efficiency.

Practical Considerations Before Adopting Liquid Feeding

Before switching or designing a liquid feeding system, several technical and operational aspects should be considered:

Feedstock Characteristics

Assess the dry matter (DM) content, ideally between 8–12% for liquid feeding.

Identify potential materials requiring pre-treatment (e.g. maceration, heating, or enzymatic hydrolysis).

Tank and Pipe Design

Ensure pipelines are designed with appropriate diameters and slopes to avoid settling.

Consider the use of progressive cavity or rotary lobe pumps for viscous materials.

Automation and Monitoring

Use flow sensors and automatic dosing control to fine-tune feeding frequency and volume.

Integrate SCADA or PLC systems to track performance in real-time.

Integration with Existing Infrastructure

Evaluate whether existing tanks, mixers, and pumps are compatible.

Plan for retrofit opportunities if converting from solid to liquid feeding.

Health and Safety

You should make sure to always incorporate spill containment and ventilation measures in feedstock preparation and transfer areas.

Common Questions About Liquid Feeding

Does liquid feeding require new infrastructure?

Not necessarily. Many plants retrofit their existing feed systems with pumps and slurry tanks at moderate cost.

What feedstocks work best in liquid systems?

High-moisture materials like slurry, digestate blends, or pre-processed food waste are ideal.

Is liquid feeding suitable for small-scale plants?

Yes – smaller farm-based units benefit from simpler operation, automation, and reduced maintenance.

Can liquid and solid feeding be combined?

Hybrid systems are common, where liquid feed handles base-load substrates while solids supplement high-energy materials.

The Future of Feeding Systems in AD

As the AD industry moves towards higher efficiency and automation, liquid feeding is becoming the standard approach for modern plants. Its compatibility with digital process control, reduced maintenance needs, and superior substrate handling make it an attractive option for both new installations and upgrades.

Moreover, with growing interest in co-digestion and circular resource use, flexible feeding systems are essential to handle diverse organic inputs.

Looking to improve your plant’s efficiency or retrofit your feeding system?

Book a consultation with our BIOCON Group team to discuss how liquid feeding could transform your AD operation.